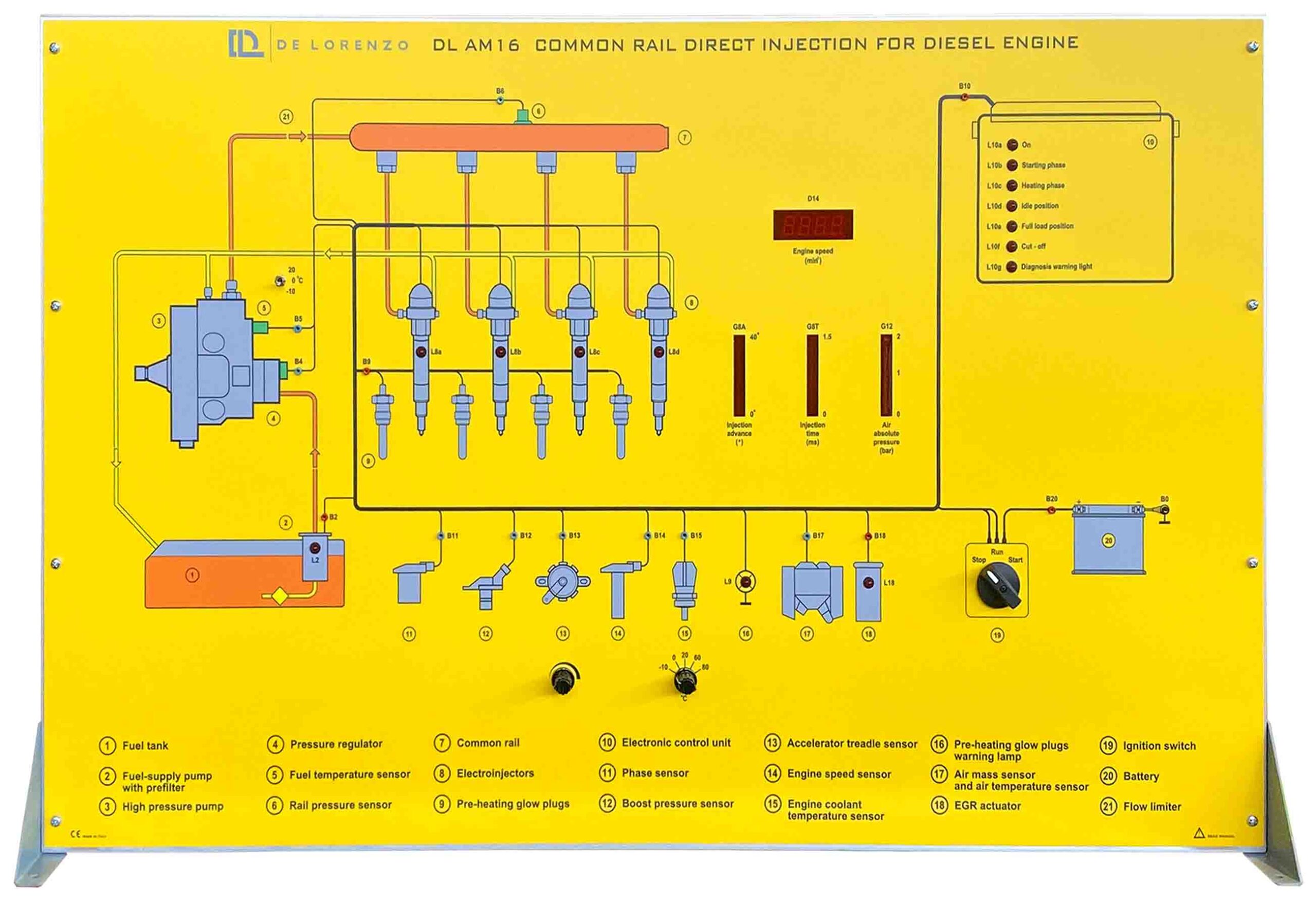

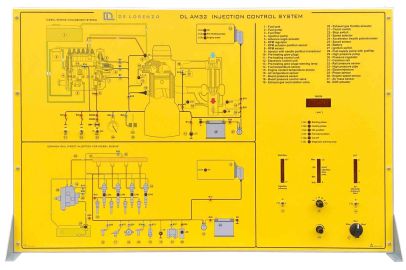

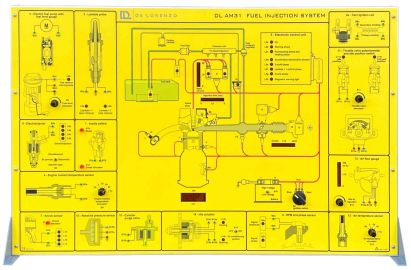

COMMON RAIL DIRECT INJECTION FOR DIESEL ENGINE

This simulator allows the study, the testing and the troubleshooting on HDI (CDI – CR) injection systems for diesel engines.

Similarly to what happens for the traditional injection petrol engines, where, the pressure of the fuel is only few bars, the HDI injection system uses a high pressure (up to 1500 bar) electric pump and a single manifold (common rail) to connect the pump to the electro-injectors.

These are electronically and individually controlled for what concerns the start and the duration of the injection.

In the conventional diesel engine, the rotation speed of the engine controls the pressure to the injectors and, furthermore, pressure and injection are strictly correlated, because only when the pressure exceeds a given threshold there is the mechanical opening of the injector.

Therefore, the advantages of the common rail are rather evident:

- High pressure also at low regimes;

- Excellent atomization and dispersion of the fuel;

- Increase of the torque;

- Reduction of the noise;

- Reduction of the consumptions and of the emissions.