SOLID AND CLOSED STATION

With the new industrial revolution, software, hardware, and processes are integrated so that a “Push” production (manufactured first and then sold) becomes a “Pull” production (only what the consumer requests is manufactured).

The digital transformation applied to the industry is characterized by the total interaction between the elements and processes that constitute a production unit.

Our didactic system is designed to integrate the knowledge of different areas or departments within a company.

Therefore, students from different careers can interact, learn, and apply concepts from their specialization area “hard skills” and study concepts from other knowledge areas.

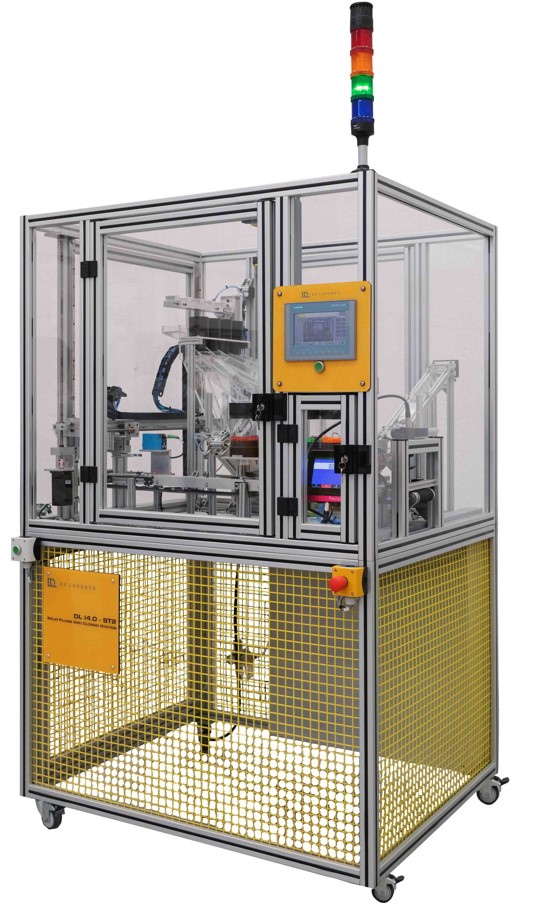

This Filling and Labelling station (DL I4.0-ST2) is where the POs (Production orders) are executed.

It communicates with the Storage and Feeding station (DL I4.0-ST1) through a conveyor belt, from which it receives the necessary material.

A cartesian robot pours the plastic beads of different colours into the containers according to the recipe defined in the Software.

Once the PO is completed, the containers are closed and labelled with a spray printer, and then transferred, also through a conveyor belt, to the next station, Sorting and Packaging (DL I4.0-ST3), for final processing.