INTERACTIVE PLC TRAINER FOR INDUSTRIAL PROCESSES

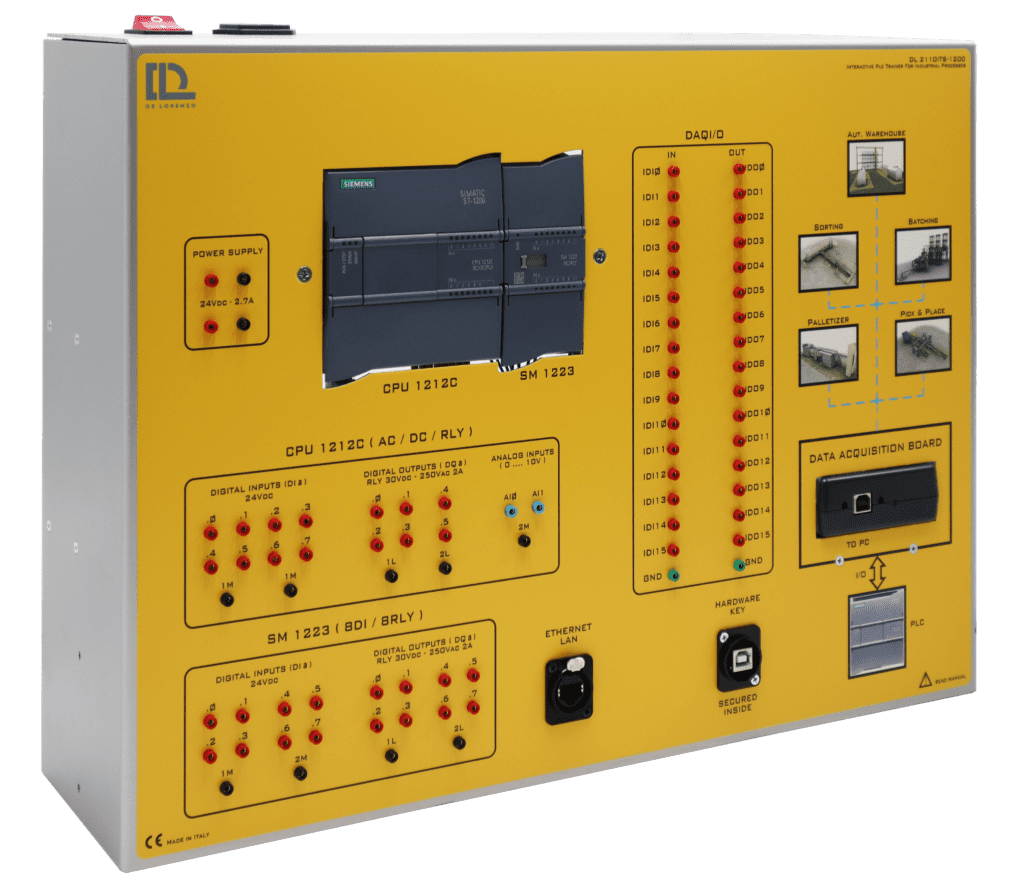

The DL 2110ITS is a training tool for PLC programming, that uses a PLC SIEMENS (SIMATIC S7‐1200 series) and an interactive educational software for the simulation of industrial environments to be controlled.

HOW DOES IT WORK? The DL 2110ITS offers five virtual industrial processes to learn how to program a PLC, with real situations of sorting, batching, palletizing, pick and place and automatic warehousing.

Each process reproduces the visual simulation of an industrial situation, including virtual sensors and actuators, so that the state of the system is “sensed” and controlled by the PLC: the objective is to program the PLC to control each of the five virtual processes as if they were real systems.

The information is exchanged between the PLC and the virtual system through a data acquisition board (DAQ) provided with 32 I/O isolated channels and USB interface.

MAIN FEATURES

- PLC Siemens of the SIMATIC S7‐1200 series

- 3D realistic graphics

- Real‐time physics that closely emulates what happens in real life

- 3D real‐time sound

- Total interactivity with the systems

- Friendly user interface

- Easy and fast to setup Based on the latest PC technology, the DL 2110ITS makes PLC training easy and fun.

Virtual environments have never been so real, featuring cutting‐edge 3D real‐time graphics, sound and total interactivity.

The result is an immersive simulated environment that allows highly realistic training processes, without any risk of injury to man or damage to machines.

The automation tasks are presented with increasing levels of difficulty, so that users can progress to more advanced exercises as they improve their skill.

The DL 2110ITS presents five training processes based on real world industrial scenarios.

Each process offers standard problems found in PLC programming, presented in order of increasing level of difficulty.

DESCRIPTION OF THE PROCESSES SORTING: transport cases from the entry bay to the elevators, sorting them by height

BATCHING: mix three primary colors (red, green and blue) in order to obtain a desired color

PALLETIZER: palletize cases up to three layers

PICK & PLACE: place parts inside boxes through a three axes manipulator

AUTOMATIC WAREHOUSE: transport, store and retrieve boxes from a rack

FAULT SIMULATION The DL 2110ITS allows you to simulate failures in sensors and actuators.

These failures can be in open circuit or short‐circuit.

With this feature the user is able to induce malfunctions in the system, presenting new challenges and increasing the realism of the simulation.

INTERACTIVITY

- Interact with the system as you would in a real system

- Add and remove objects from the production circuit, at any time during the simulation

- Cause error situations or system jams

- Test individual parts of the system; for example: test a conveyor table